Wastewater in Cereal Production

AI Driven Control and Analytics Consistently Delivers Cleaner Wastewater While Reducing Total Cost

The Streamwise D.I.™ Solution:

Streamwise D.I.™ technology for DAF is helping an Australian small goods meat processor significantly improve its waste treatment operations through:

– Robust online sensors

– Proprietary AI based chemical control

– 24/7 performance monitoring, alarm notification and expert oversite

Background

Cereal production is a water intensive operation. It generates a large quantity of wastewater containing high levels of total suspended solids and organics. Wastewater treatment presents a total cost impact on chemicals, trade waste charges and labor requirements.

Food processors are looking for innovative ways to improve their wastewater treatment performance and lower their overall operating costs while increasing their personnel efficiency.

Opportunities

An Australian food manufacturing facility producing various cereal products generates on average 700kL of wastewater per week. Wastewater is processed through a Dissolved Air Flotation (DAF) unit using a manual chemical feed program to adjust pH and allow TSS removal.

With a need to reduce overall water consumption and the loss of experienced DAF operators, the plant processors searched for ways to automate and optimize the wastewater operations. They consulted us on the use of its Streamwise D.I.™ for DAF automation technology to:

1. Improve DAF efficiency and consistency, allowing for recycling opportunities to support the corporate water conservation objectives.

2. Reduce DAF Total Cost of Operation by lowering trade waste charges, optimizing waste treatment chemical dosing, and minimizing operator oversight.

Streamwise D.I.™ Results

Table 1

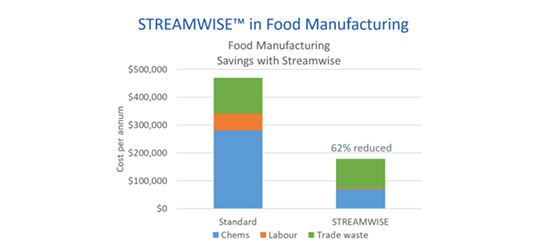

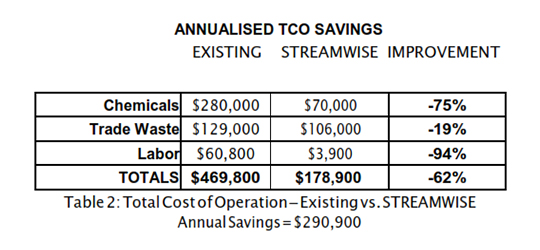

In Table 1, we see how the Streamwise D.I.™ proprietary control vs manual control significantly lowers the plant’s total cost of operation. Streamwise D.I.™ control reduced trade waste charges by 19% and chemical costs by 75%. Ultimately, the Streamwise D.I.™ system will save this food processor over $290,000 per year. In addition to considerable TCO savings given the more consistent low TSS effluent, the plant is in the planning stages of running an MBR trial to recycle part of the waste stream.

Streamwise D.I.™ for DAF technology is helping this food processor produce cleaner and more consistent wastewater that is suitable for further in-house processing to allow water reuse and recycle.

In addition, this consistent and better-quality water is produced using significantly less treatment chemistry and operator involvement resulting in an overall TCO savings of 62%.

Streamwise D.I.™ technology continually optimizes DAF operations, automatically responding to variations in feedwater quality and quantity. Reliable online sensors monitor DAF inlet and outlet water quality every 3 seconds, proprietary AI-driven control algorithms optimize system performance in real-time, and cloud based analytics provides continuous improvement insights. This comprehensive IIoT approach to wastewater operations ensures the best performance at the lowest cost.

Get more from Streamwise D.I.™

Request demo

Like to see Streamwise D.I.™ in action? Please contact us to arrange a demonstration.

Request information pack

Like to learn more about how Streamwise D.I.™ can save you money? Please contact us for an information pack.

Stay in touch

Like to keep in touch with us? Please sign up for our newsletter.